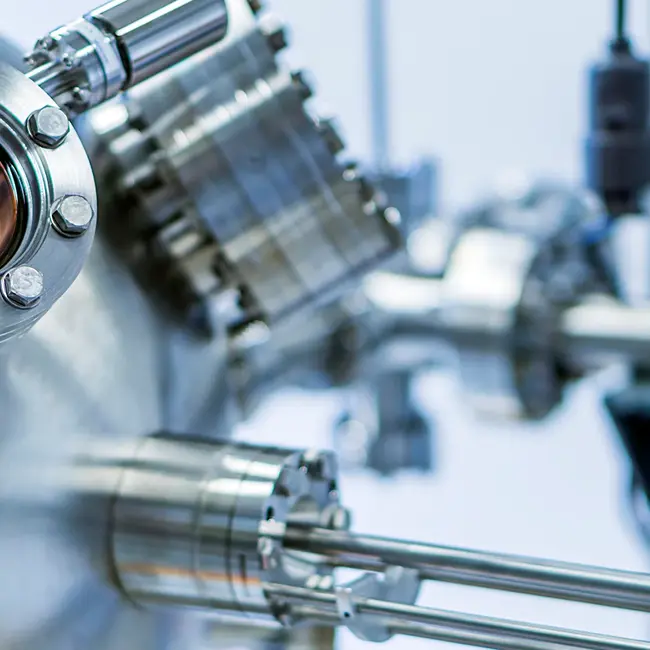

Equipment

CONTACT

20.01.2026 - 22.01.2026

SPIE Photonics West 2026

San Francisco, CA, USA

The Moscone Center

Booth 2261

17.03.2026 - 19.03.2026

H2 & FC Expo Tokio 2026

Tokyo, Japan

Tokyo Big Sight

07.04.2026 - 10.04.2026

China Glass 2026

Shanghai, China

Shanghai New International Expo Center

N1 / 181

07.05.2026 - 09.05.2026

TiExpo 2026

Shanghai, China

National Exhibition and Convention Center

A006

05.07.2026 - 10.07.2026

SPIE Astronomical Telescopes + Instrumentation 2026

Copenhagen, Denmark