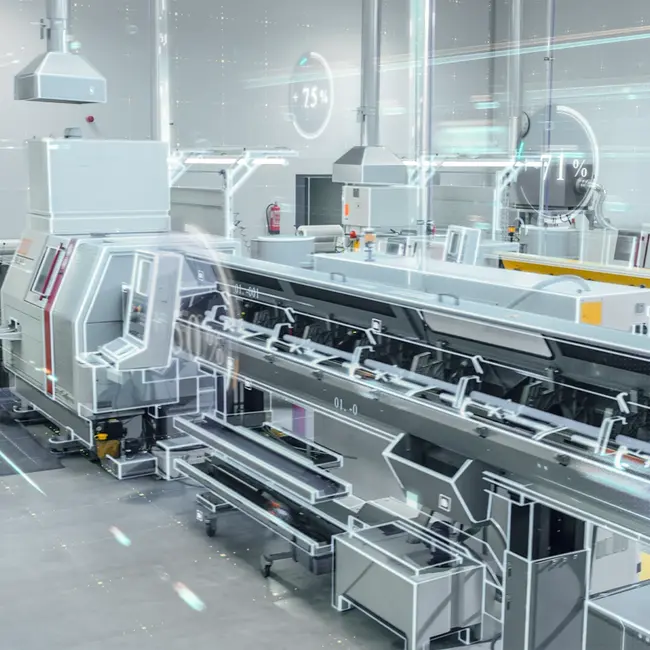

The innovative high-vacuum coating platform of the HS-GROUP, known as NOVAWEB, effectively bridges the challenge between productivity and adaptability. Additionally, it meets the requirements of both the current and future markets.

NOVAWEB is the ideal choice for both production purposes and research and development projects (R&D). Its remarkable potential lies in its ability to accommodate up to six double-tube magnetrons and integrate a wide range of in-situ measurement sensors. This unique configuration gives the machine exceptional productivity in manufacturing contexts while simultaneously offering remarkable flexibility and versatility when used for R&D purposes.

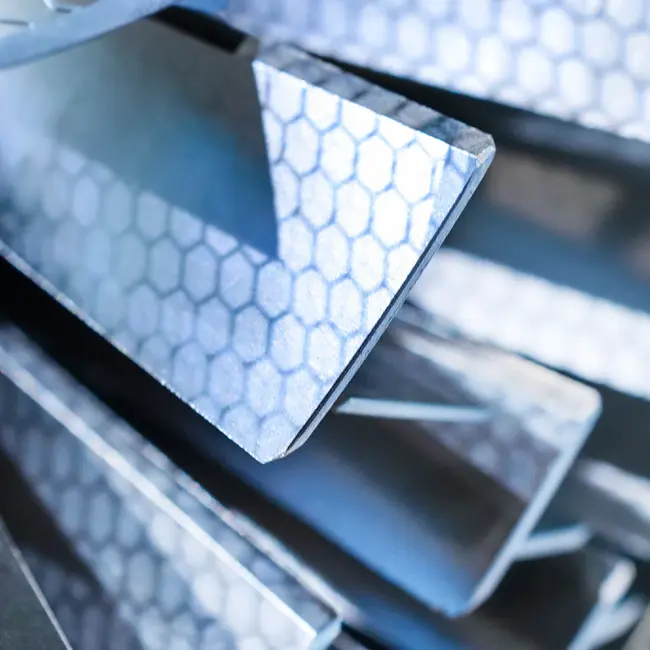

This versatility positions NOVAWEB as the primary option for applications such as ITO films, flexible printed circuit boards (FPCB), low-E coatings, and smart glass. Based on our own tube magnetrons, the NOVAWEB platform serves as a solid foundation for achieving high productivity.

Furthermore, the optional gas separation capability of NOVAWEB between adjacent process sections enables the deposition of an extensive range of conceivable layer combinations of metals and dielectrics in a single pass.

In addition to its ability to perform both reactive and non-reactive sputtering processes, NOVAWEB can be equipped with various in-situ sensors. These sensors allow continuous and precise monitoring of desired physical layer properties such as resistivity, reflection, and transmission, enhancing the overall control and optimization of the coating process.